Yogi Tea, a leading multinational company in the production of organic and Ayurvedic herbal teas, has entrusted Cefla with the role of General Contractor for a complex and multifaceted project with very challenging deadlines.

Strengths

Complete general contractor

Cefla managed the entire project, from design to implementation, coordinating all construction and installation phases.

Efficiency and speed

Despite the difficulties caused by the pandemic, the project was completed in record time, with the production plant delivered in April 2020 and the office building in May 2020.

Sustainability and innovation

The new facility is equipped with advanced technological systems and has obtained B-Corp certification, reflecting TeaPak's commitment to responsible and sustainable business practices.

Key Numbers

57.000 m²

Total surface area

10.000 m²

Production facility surface area

1.300 m²

Office building surface area

Background

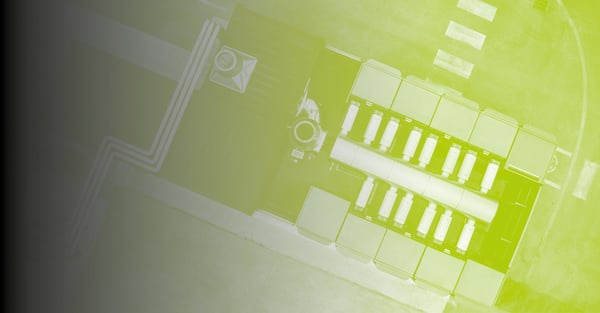

TeaPak, part of the international Yogi Tea group, has decided to consolidate and expand its presence in Imola with the construction of a new production plant.

The project is part of the company's growth strategy, aimed at meeting the growing demand for herbal teas in Europe.

Challenges

- Management during the pandemic

The project was carried out during the lockdown caused by Covid-19, requiring the adoption of strict safety protocols to ensure the continuity of work and the safety of workers. - Multidisciplinary coordination

The need to integrate different technical and managerial skills required effective collaboration between Cefla and local partner companies.

Project Tasks

Cefla handled the entire project, carrying out excavation, earthworks and road embankments, foundations, prefabricated reinforced concrete structures and all finishing works, as well as the construction of a cogeneration plant with hot/cold heat pumps.

The project consists of three buildings:

- the “office” building, built on two floors, with spaces designed for operational staff, including the canteen and changing rooms, and, of course, the offices for all employees on the upper floor;

- the “factory” building, where the warehouses for raw materials and finished products are located, with the production area in between;

- the “systems” building, i.e. the building housing the systems for the production of hot and cold water for production purposes, the electrical rooms and service rooms used by Teapak.

In addition to its technical features, the new structure stands out from an aesthetic point of view thanks to the facades of the office building, built with long multicoloured aluminium slats distributed vertically to echo the brand logo, as well as a 12-metre-high external fire tank, from which all the pipes and ducts serving the plant architecture branch out.

The entire plant is also served by a photovoltaic system, in addition to a dedicated integrated purification and dust abatement system for each individual herbal tea production and packaging machine.

Implementation

The plant engineering solutions include:

- storage, pumping and primary distribution systems for fire-fighting water lines;

- water pumping and primary distribution systems; condensation systems for building air conditioning systems;

- control rooms for Towers A-B-C and the Podium;

- installation of a generator set for each building to power general systems, and an additional 4 common generator sets to power more sensitive systems;

- air conditioning and forced ventilation systems for garages;

- plumbing systems (a “variable” volume system is used to ensure minimum pumping costs and minimum energy consumption);

- fire-fighting systems;

- automatic control of mechanical and lighting systems;

- special electrical safety systems.

Download

Gallery

+6

Tutte le foto (12)

Case Study

EPC Contracting

EPC Contracting

Sea Linate Malpensa

CEFLA enhances Milan's Linate and Malpensa airports with advanced plant engineering, ensuring...

EPC Contracting

EPC Contracting

M9 Museum of the Twentieth Century

The M9 Museum in Mestre: an example of urban regeneration and energy sustainability thanks to...

EPC Contracting

EPC Contracting

Cà Litta

Technological redevelopment of Cà Litta in Milan: advanced solutions and respect for historical...

EPC Contracting

EPC Contracting

City of Cultures

Cefla has integrated advanced technologies and sustainable energy systems into Milan's City of...

EPC Contracting

EPC Contracting

Rome Metro

Redevelopment of the Termini junction in Rome: Cefla improves safety, efficiency and accessibility...

EPC Contracting

EPC Contracting

Unipol Midi

Learn about the construction of the Unipol Midi complex in Bologna: integrated design, energy...

EPC Contracting

EPC Contracting

TeaPak

Cefla builds a new production plant for TeaPak in Imola, completed during the pandemic, with...

EPC Contracting

EPC Contracting

Crif CED

Installation and certification of a state-of-the-art data center for CRIF, with architectural...

EPC Contracting

EPC Contracting

Le Cotoniere

Learn how Cefla integrated advanced systems into Salerno's Le Cotoniere Shopping Center, improving...

EPC Contracting

EPC Contracting

FICO Eataly World

Learn how Cefla contributed to FICO Eataly World with sustainable and energy-efficient plant...

News

Racing Bulls Green Energy Park: the new era of sustainable motorsport

25 February 2026

Visa Cash App Racing Bulls unveils Cefla's innovative fuel cell plant in the new "Racing Bulls Green Energy Park"

Are you ready for KEY - The Energy Transition Expo 2026?

25 February 2026

Attend KEY - The Energy Transition Expo 2026 to discover the latest sustainable technologies and innovative solutions for the energy transition.

Energy HUB: from concept to implementation. The Itala case study

24 February 2026

Learn how with Cefla, Itala is revolutionizing the dairy sector with innovative and sustainable energy solutions at its new production facility.

Find the perfect solution for your business