New sub-intensive care unit at the Pisa University Hospital.

EPC Contracting for Cisanello Hospital

Cefla was the lead company in the team that carried out the project for the new sub-intensive care unit at the Pisa University Hospital. The project involved structural, construction, functional, plant engineering and technological aspects.

Strengths

Creation of a high-tech department

Cefla oversaw the design and installation of all the technological systems in the new Sub-Intensive Care Unit, ensuring high standards of safety and functionality.

Flexibility of use

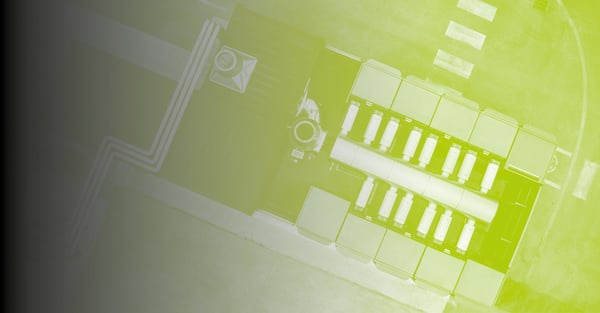

The department has 12 beds, designed to be converted into intensive care beds, thus offering a versatile response to different clinical needs.

Advanced pressure gradient control

The air treatment system was designed to ensure pressure gradient control, which is essential for the safe management of infectious or immunocompromised patients.

Key Numbers

12

Critical care beds

Hygienic air replacement up to

12 vol/h

Background

The Pisa University Hospital has started a project to upgrade its healthcare facilities in order to deal with health emergencies and improve the care it provides. The new Sub-Intensive Care Unit is part of this project, offering state-of-the-art facilities and technology for the treatment of infectious and immunocompromised patients.

The complexities involved in working on an existing, functioning hospital building made it necessary to develop a detailed construction plan that complies with the regulations for Hospital Safety Class 4 according to the 2018 Technical Construction Regulations.

Challenges

- Complexity of the operating environment

The department was built in a busy hospital environment, requiring careful planning to minimise interference with ongoing healthcare activities. - Management of interference between systems

The distance of approximately 70 metres between the department and the main newly installed equipment presented a significant challenge, which was overcome through proactive interaction with the healthcare staff.

Project Tasks

Cefla was responsible for:

- The rearrangement of the rooms.

- The complete overhaul of the electrical and data transmission systems.

- The installation of an air treatment system to control pressure gradients.

- The new distribution of the medical gas system and bed headboards.

Implementation

All clinical engineering systems, technological networks and the positioning of new machinery using specialised lifting equipment have been set up, in addition to safety works such as metal staircases and guardrails. Cefla managed the complete installation of electrical, mechanical and special systems—including supervision, data network and safety—and the coordination of structural reinforcements for static and seismic safety. All systems and false ceilings have been installed with anti-seismic systems in compliance with regulations.

The intensive and sub-intensive care rooms are equipped with mechanical ventilation with differentiated pressure, which guarantees isolation and safety for both infectious and immunocompromised patients. There are constant flow diffusers and VAV boxes, with sanitisation mode activated via touch screen or dedicated selector, and devices for the safe replacement of HEPA H14 filters.

Each room has a dedicated electrical panel, with automatic switching management via PLC and class 0 safety power supplies for critical utilities. The lighting, mainly dimmable LEDs, is automated via sensors and a DALI system; emergency power is provided by uninterruptible power supplies.

Air conditioning is provided by an all-outside air system with heat recovery, humidifier and redundant 220 kW chiller. Local air distribution branches are equipped with post-coil heating and H14 absolute filters, with electronic control of microclimatic parameters. The entire sub-intensive area is managed by a centralised BMS, with pressure control via touch panel and communication via V-Lan network.

Download

Gallery

Tutte le foto (3)

Case Study

EPC Contracting

EPC Contracting

Sea Linate Malpensa

CEFLA enhances Milan's Linate and Malpensa airports with advanced plant engineering, ensuring...

EPC Contracting

EPC Contracting

M9 Museum of the Twentieth Century

The M9 Museum in Mestre: an example of urban regeneration and energy sustainability thanks to...

EPC Contracting

EPC Contracting

Cà Litta

Technological redevelopment of Cà Litta in Milan: advanced solutions and respect for historical...

EPC Contracting

EPC Contracting

City of Cultures

Cefla has integrated advanced technologies and sustainable energy systems into Milan's City of...

EPC Contracting

EPC Contracting

Rome Metro

Redevelopment of the Termini junction in Rome: Cefla improves safety, efficiency and accessibility...

EPC Contracting

EPC Contracting

Unipol Midi

Learn about the construction of the Unipol Midi complex in Bologna: integrated design, energy...

EPC Contracting

EPC Contracting

TeaPak

Cefla builds a new production plant for TeaPak in Imola, completed during the pandemic, with...

EPC Contracting

EPC Contracting

Crif CED

Installation and certification of a state-of-the-art data center for CRIF, with architectural...

EPC Contracting

EPC Contracting

Le Cotoniere

Learn how Cefla integrated advanced systems into Salerno's Le Cotoniere Shopping Center, improving...

EPC Contracting

EPC Contracting

FICO Eataly World

Learn how Cefla contributed to FICO Eataly World with sustainable and energy-efficient plant...

Notizie

Racing Bulls Green Energy Park: the new era of sustainable motorsport

25 February 2026

Visa Cash App Racing Bulls unveils Cefla's innovative fuel cell plant in the new "Racing Bulls Green Energy Park"

Are you ready for KEY - The Energy Transition Expo 2026?

25 February 2026

Attend KEY - The Energy Transition Expo 2026 to discover the latest sustainable technologies and innovative solutions for the energy transition.

Energy HUB: from concept to implementation. The Itala case study

24 February 2026

Learn how with Cefla, Itala is revolutionizing the dairy sector with innovative and sustainable energy solutions at its new production facility.

Find the perfect solution for your business