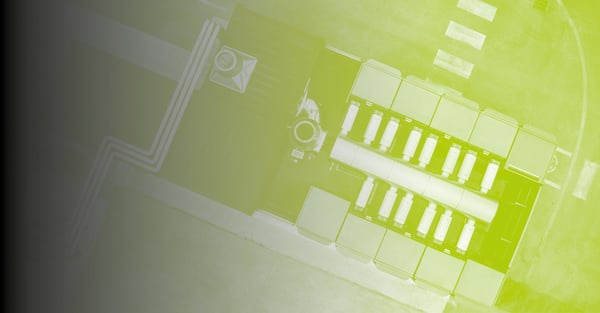

Kaleseramik has entrusted Cefla Impianti with upgrading the control and supervision system for the entire cogeneration plant at its two factories in Cannakale and Kalebodur, which make up the Can plant, as well as engineering for the installation of a new atomiser.

Strengths

Advanced digitisation

Cefla has implemented a state-of-the-art control and supervision system for the entire cogeneration plant, improving operational efficiency and energy management.

Multi-site integration

The new system enables centralised management of Kaleseramik's two factories, located in Çanakkale and Kalebodur, optimising operations and maintenance.

Reliability and safety

The upgrade has improved the operational safety and resilience of the plant, ensuring continuous and reliable energy production.

Key Numbers

2

Plants involved

22.500 kWe

Electrical power

Background

The partnership between Cefla and Kaleseramik began over 20 years ago with the construction of a cogeneration plant that enabled the company to significantly reduce its emissions and energy costs.

Challenges

- Technological modernisation

Upgrade of an existing control system to meet current efficiency and sustainability requirements. - Business continuity

Implementing the upgrade without disrupting daily production operations.

- Staff training

Ensuring that the internal team is adequately trained to use the new system effectively.

Project Tasks

Cefla designed and implemented a customised control and supervision system for Kaleseramik's cogeneration plant. The project included the installation of advanced hardware and software, integration with existing systems and staff training to ensure a smooth and efficient transition.

Implementation

The project was successfully completed, with an immediate positive impact on energy efficiency and operational management at Kaleseramik's plants. The upgrade has helped strengthen the company's position as a leader in the ceramics industry, highlighting the importance of technological innovation in industrial production.

The project involved the installation of a new atomiser with a water evaporation capacity of 25,000 litres per hour, connected to the existing cogeneration system and an additional system to recover heat from the kilns in order to maximise the use of existing thermal energy.

Cefla was responsible for the design and manufacture of the main mechanical components, instrumentation and components for the heat recovery system, as well as the supply of automation and supervision control devices (software and hardware). The advanced automation system allows one or more turbines to be used depending on the electrical energy required by the plants. Three Siemens gas turbines, with a total power of 21 MW, feed nine atomizers through their exhausts and supply electricity to all the plants. A fibre optic network transfers the control signal for all units at high speed, while the new software ensures monitoring of the entire system through an intuitive user interface, constant recording and reporting of functional data.

Download

Gallery

Tutte le foto (2)

Case Study

Power Generation

Power Generation

Acea Tor di Valle

Renovation of the Tor di Valle district heating plant to improve energy efficiency and...

Power Generation

Power Generation

Nupi Industrie Italiane

Cefla's innovative trigeneration solution for Nupi Industrie Italiane in Busto Arsizio, optimizes...

Power Generation

Power Generation

A2A

Learn how CEFLA built an advanced reserve power plant in Cassano d'Adda, ensuring reliable and...

Power Generation

Power Generation

Nuova Riwal Ceramiche

High-efficiency cogeneration plant installed by Cefla for Nuova Riwal Ceramiche, improving...

Power Generation

Power Generation

Olivieri Carni

Olivieri Carni chose Cefla for a trigeneration plant, improving energy efficiency and reducing CO₂...

Power Generation

Power Generation

Effeffe Pet Food

Cefla's high-efficiency cogeneration plant for Effeffe Pet Food: reducing energy costs and...

Power Generation

Power Generation

Florim

Learn how Cefla improved energy efficiency at Florim's Mordano plant with a new 8,300 kWe...

Power Generation

Power Generation

Hera Central District Heating Plant

Hera cogeneration power plant in Bologna: improved energy efficiency and reduced CO₂ emissions...

Power Generation

Power Generation

Kaleseramic

Innovative upgrade of Kaleseramik's cogeneration plant, improving energy efficiency and...

Power Generation

Power Generation

SACA

Cefla optimizes SACA's energy efficiency and environmental sustainability with a natural gas...

News

Racing Bulls Green Energy Park: the new era of sustainable motorsport

25 February 2026

Visa Cash App Racing Bulls unveils Cefla's innovative fuel cell plant in the new "Racing Bulls Green Energy Park"

Are you ready for KEY - The Energy Transition Expo 2026?

25 February 2026

Attend KEY - The Energy Transition Expo 2026 to discover the latest sustainable technologies and innovative solutions for the energy transition.

Energy HUB: from concept to implementation. The Itala case study

24 February 2026

Learn how with Cefla, Itala is revolutionizing the dairy sector with innovative and sustainable energy solutions at its new production facility.

Find the perfect solution for your business