Powering the future

Are you ready for the future of Power Generation?

+

energy efficiency

-

environmental impact

+

cost saving

+

Energietic Reliability

Want to find out the economic benefits of CHP? Contact our sales engineers now!

Cefla has more than 40 years' experience in the construction of energy production systems, such as cogeneration and trigeneration using methane gas, through the use of endothermic engines and turbines.

EPC Contracting's Approach

Starting from the specific and detailed feasibility analysis, to the turnkey proposal of the entire plant, all the way to the subsequent maintenance, we support clients throughout the entire process, even accompanying them during operation.

Cogeneration

The simultaneous production of electrical and thermal energy from a single primary source (CHP - Combined Heat and Power) generates important efficiencies: cogeneration exploits the thermal energy that would otherwise be lost in the electricity production process and enables energy cost savings of up to 40% of the total cost of electrical, thermal and refrigeration supply.

Cefla began in the 1980s to build cogeneration plants, initially in the ceramic industry, which is particularly energy-intensive and interested in generating efficiency and savings through self-generation of energy.

Today there are many customers Cefla has partnered with over the years, in the most diverse sectors:

- industry (ceramic, steel, food, pharmaceutical, chemical, manufacturing in general ... )

- shopping and business centers

- large district heating plants that provide light and heat to up to even 100,000 people.

Trigeneration

Cefla, over the years has built many trigeneration plants for the production of chilled water (>7°C) through the use of Lithium Bromide refrigerant absorbers that use part of the heat from cogeneration. This configuration leads to savings from decreasing the electrical consumption of existing chiller units.

But that's not all. To meet the needs of companies in the food sector (e.g., frozen food) and beyond, Cefla also builds "sub-zero" trigeneration plants that, through the use of ammonia absorbers, allow temperatures as low as -40°C to be reached.

The benefits

- energy efficiency

- reduction of greenhouse gas emissions (CO2)

- energy emission certificates (white certificates)

- environmental benefit

- continuity of energy supply (island operations)

- use of energy sources with incentive system

- subsidized tax regimes (methane defiscalization)

Stages of implementation

Want to learn more about other solutions?

NOVA Solution by Cefla

Design, construction and management of innovative cogeneration and trigeneration plants that integrate SOFC Fuel Cell technology for the production of clean, highly efficient energy that eliminates polluting emissions into the atmosphere.

NOVAbio Solution by Cefla

Design, construction and management of innovative cogeneration plants that integrate SOFC Fuel Cell technology for the production of clean, highly efficient energy, which eliminates polluting emissions into the atmosphere, in particular for the Biogas and Biomethane sector.

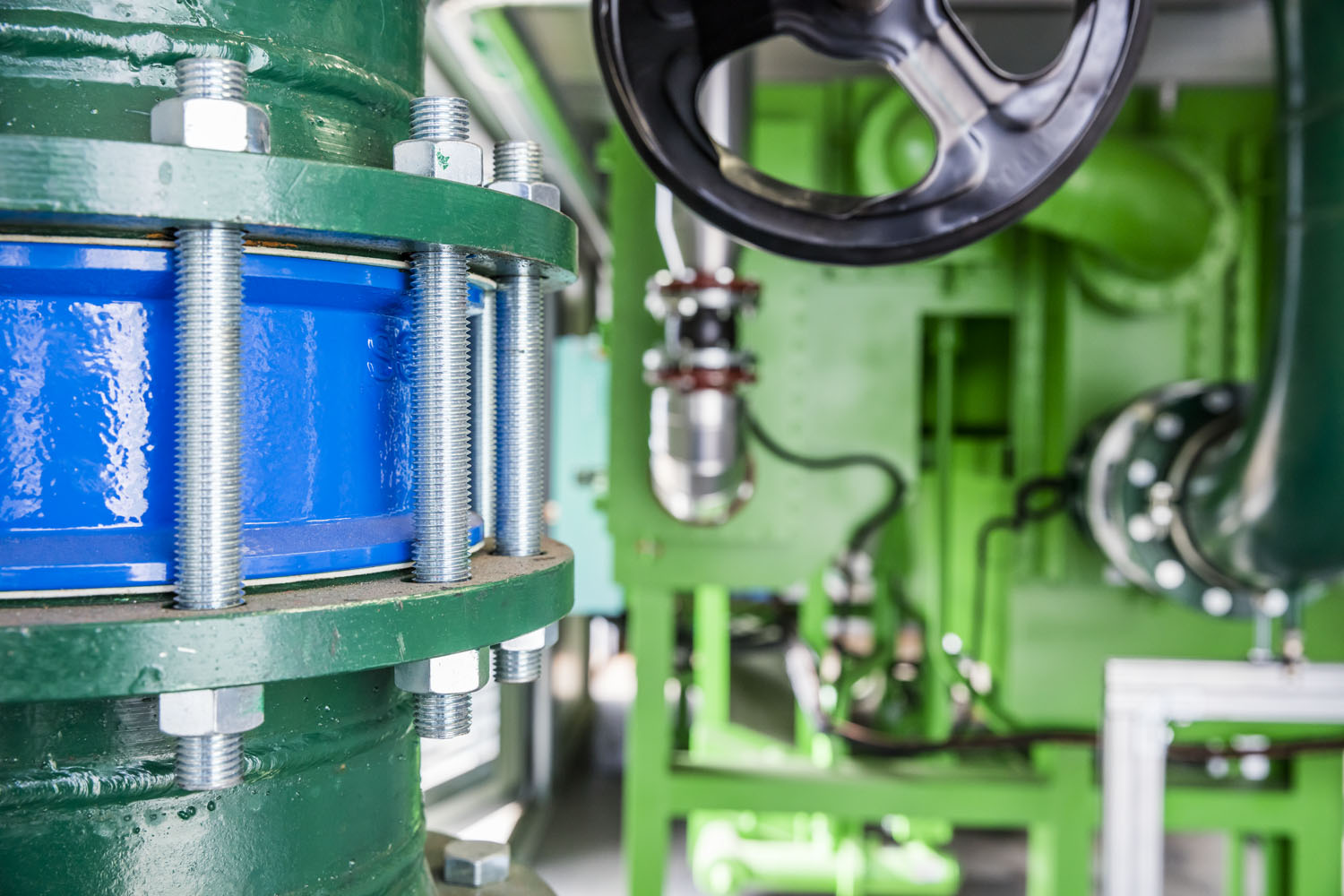

Cogeneration | engines and turbines

Design, construction and management of cogeneration and trigeneration plants, for the self-production of electrical energy, thermal energy and cooling energy, through internal combustion engines and turbines, with the use of methane gas as the primary source.

Energy HUB

Design, construction and management of a technological hub integrated into the production plant in an industrial environment (e.g. cogeneration or trigeneration plant, thermal, water and compressed air plant, purification plants, etc.), which generates efficiency and optimizes its management in a sustainable way.

Looking for a partner to implement your cogeneration plant or to make your business more efficient?

Fill out the form to learn more about your needs together

Services

Project Consulting

Our strength lies precisely in our engineering expertise, to support our customers right in the initial analysis and design phases.

Find out moreEnergy Efficiency and Decarbonisation

The search for efficiency and design in the field of energy transition are the driving force behind our most visionary projects.

Find out moreIngegneria di manutenzione

Maintenance engineering guides our management and maintenance approach, for technological utilities, manufacturing processes, and energy production plants.

Find out moreWhy Choose Cefla

Partnership

Cefla's long history and expertise in the construction of complex facilities, solid financial structure, and high level of reliability make it the ideal partner in the design, implementation, and management of the most challenging projects, with a focus on efficiency and sustainability issues.

Sustainability

Our engineering and implementation experience, cross-functional skills and innovative solutions we have created allow us to work alongside clients and be their single point of contact and reference, with a partnership approach, to support them on even the most visionary projects of environmental sustainability, decarbonization and energy transition.

Value Engineering

The support in the design phase of specific needs and the engineering consulting structure that I have created, with special expertise gained precisely in the implementation of energy production and energy efficiency plants, directly involves us in achieving common goals.

Case Study

Power Generation

Power Generation

Acea Tor di Valle

Ristrutturazione della centrale di teleriscaldamento di Tor di Valle per migliorare efficienza...

Power Generation

Power Generation

Nupi Industrie Italiane

Soluzione di trigenerazione innovativa di Cefla per Nupi Industrie Italiane a Busto Arsizio,...

Power Generation

Power Generation

Sacmi

Scopri come Cefla ha migliorato l'efficienza energetica di SACMI con un impianto di trigenerazione...

Cefla assists the customer in all phases after the plant or power plant is tested, in the years to come, with specialized maintenance and/or operation services, through a maintenance engineering approach that integrates digital systems and technologies.

Cefla's more than 40 years of experience in the maintenance of multi-brand motor-based power generation plants makes it a market benchmark.

knowledge for efficency

The history of Cefla, since 1932, is the story of an Encounter with Efficiency.

The pursuit of efficiency has become the driving force behind our most innovative projects, and has enabled us over the years to support our customers in achieving their most complex goals.

Discover the columnSectors

Data Center

Discover Cefla solutions for data centers: design, 24/7 management, energy efficiency and decarbonization with advanced technologies.

Industry

Solutions for industrial design and plant maintenance: integrated technologies, efficient management, decarbonization and energy saving.

Aerospace defense

Cefla supports the aerospace sector with plant solutions, EPC, energy management and technologies for efficiency and decarbonization

Directional

Technological systems for office buildings: design, integrated management, energy efficiency and smart technologies for towers and urban complexes.

Artistic Historical

Plant solutions for the restoration of historic buildings: tailor-made technologies, efficiency and respect for artistic and architectural heritage.

Healthcare

High-performance healthcare construction: design, EPC, management and efficiency improvement of hospitals and critical facilities with advanced and sustainable technologies.

Ports, airports and exhibition spaces

Plant solutions for ports, airports and exhibition spaces: EPC, energy management, cold ironing and technologies for efficiency enhancement and decarbonization.

Retail and Contract

We build and manage systems for hotels and shopping centers: EPC, facility management, energy efficiency and technologies combining comfort and sustainability.

en.vision

Do you want to manage your energy production plant efficiently and generate savings? Discover en.vision