As part of the energy transition underway in Europe and globally, and in line with the German government's plan to replace coal-fired power plants, we have built a plant that supplies electricity and heat using the most efficient plant technologies: all the heat will be used to power the city's district heating network (almost 100,000 residents).

Strengths

Energy transition

The new plant represents a significant step towards phasing out coal, providing a sustainable and reliable energy solution for the city of Cottbus.

High efficiency

Thanks to the use of advanced technologies, the plant achieves an overall efficiency of 90%, a significant improvement on the previous figure of 70%.

Reduction in emissions

The plant contributes to an annual reduction of 100,000 tonnes of CO₂, supporting Germany's climate targets.

Key Numbers

51,9 MW

Installed electrical power

50,5 MW

Heat output

300 MWh

Heat storage capacity

tonnes/year

100.000

Reduction in CO₂ emissions

Background

Today, Cottbus has a flexible, modern power plant capable of meeting the needs of its citizens, a challenging project, a turnkey solution by Cefla.

Challenges

- Transition from coal to gas

Replace existing coal-fired power plants with an efficient gas-fired plant, ensuring continuity of energy supply. - Integration into the local energy system

Ensure that the plant integrates effectively with the existing district heating network, maintaining stability and reliability.

Project Tasks

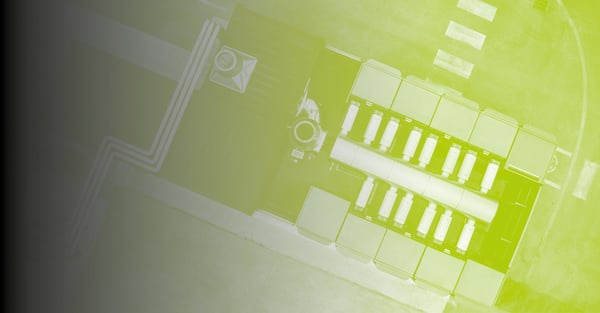

Cefla, in joint venture with Atzwanger AG, oversaw the design, construction and commissioning of the plant. The project included the installation of five Jenbacher J920 gas engines, thermal storage tanks and auxiliary systems, ensuring efficient and sustainable operation.

Implementation

The following phases were carried out between 2019 and 2023:

- Plant engineering and civil engineering works (foundation excavations, ground reinforcement, etc.)

- Installation of 15 hot water tanks, 30 metres high

- Installation of 5 Jenbacher J920 FleXtra gas engines, each with a capacity of 10 MW

- Mechanical plant engineering for the engines

- CE certification of the entire plant, including earthquake resistance

- Commissioning

The plant went into operation in September 2022, supplying electricity and heat to around 100,000 residents of Cottbus. The project was completed on schedule and in line with the required quality standards, making a significant contribution to the region's decarbonisation strategy.

Despite the complexity of the project, its positive outcome demonstrates the enormous potential of cogeneration as an extremely efficient and effective technology for decarbonisation. Annual CO2 emissions are estimated to be reduced by approximately 100,000 tonnes, a 30% reduction for the immediate well-being of citizens.

While energy production from renewable sources such as wind or solar power is subject to strong fluctuations due to variable weather conditions, cogeneration technology is more reliable. In addition, thanks to the rapid start-up system of the engines (reaching 50 MW in just 3 minutes), the Cottbus plant can respond instantly to the city's needs.

Download

Gallery

Tutte le foto (5)

Case Study

Power Generation

Power Generation

Acea Tor di Valle

Renovation of the Tor di Valle district heating plant to improve energy efficiency and...

Power Generation

Power Generation

Nupi Industrie Italiane

Cefla's innovative trigeneration solution for Nupi Industrie Italiane in Busto Arsizio, optimizes...

Power Generation

Power Generation

A2A

Learn how CEFLA built an advanced reserve power plant in Cassano d'Adda, ensuring reliable and...

Power Generation

Power Generation

Nuova Riwal Ceramiche

High-efficiency cogeneration plant installed by Cefla for Nuova Riwal Ceramiche, improving...

Power Generation

Power Generation

Olivieri Carni

Olivieri Carni chose Cefla for a trigeneration plant, improving energy efficiency and reducing CO₂...

Power Generation

Power Generation

Effeffe Pet Food

Cefla's high-efficiency cogeneration plant for Effeffe Pet Food: reducing energy costs and...

Power Generation

Power Generation

Florim

Learn how Cefla improved energy efficiency at Florim's Mordano plant with a new 8,300 kWe...

Power Generation

Power Generation

Hera Central District Heating Plant

Hera cogeneration power plant in Bologna: improved energy efficiency and reduced CO₂ emissions...

Power Generation

Power Generation

Kaleseramic

Innovative upgrade of Kaleseramik's cogeneration plant, improving energy efficiency and...

Power Generation

Power Generation

SACA

Cefla optimizes SACA's energy efficiency and environmental sustainability with a natural gas...

Notizie

Racing Bulls Green Energy Park: the new era of sustainable motorsport

25 February 2026

Visa Cash App Racing Bulls unveils Cefla's innovative fuel cell plant in the new "Racing Bulls Green Energy Park"

Are you ready for KEY - The Energy Transition Expo 2026?

25 February 2026

Attend KEY - The Energy Transition Expo 2026 to discover the latest sustainable technologies and innovative solutions for the energy transition.

Energy HUB: from concept to implementation. The Itala case study

24 February 2026

Learn how with Cefla, Itala is revolutionizing the dairy sector with innovative and sustainable energy solutions at its new production facility.

Find the perfect solution for your business